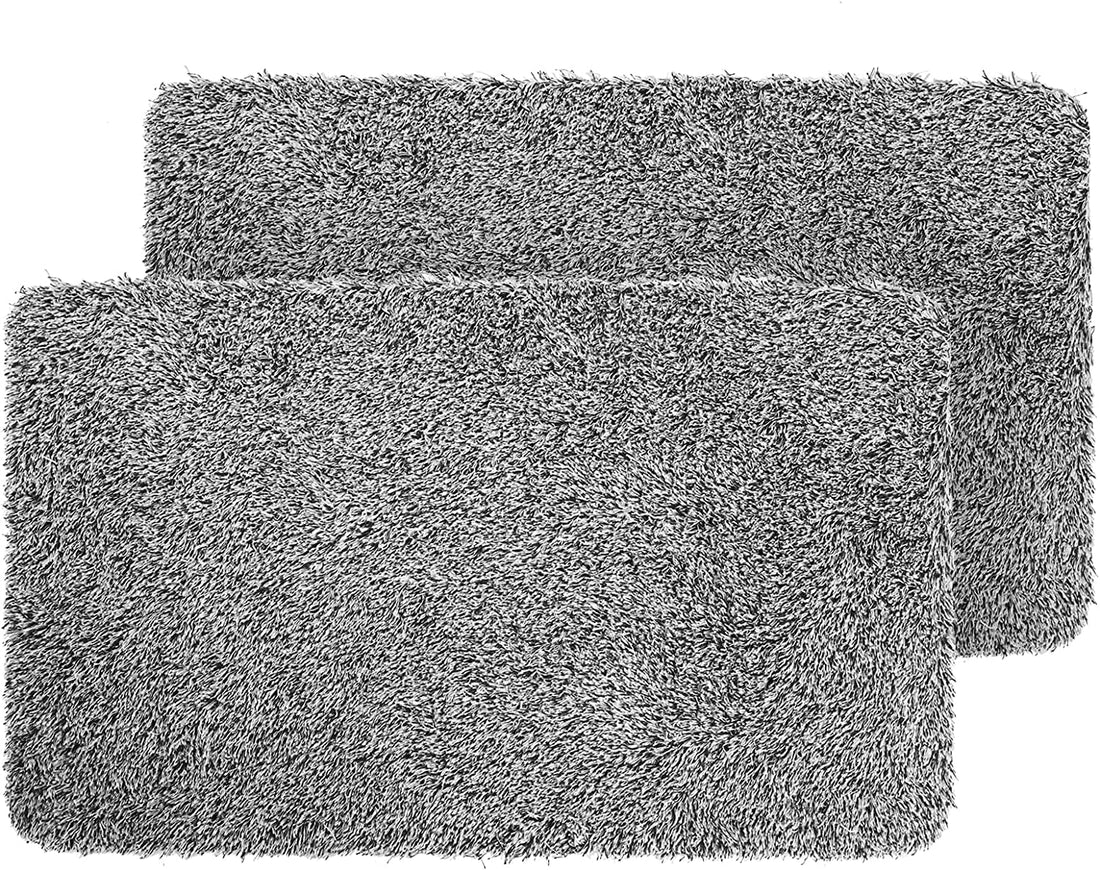

Carpet ( door mat, kitchen rug ) type and use

What is the classification of carpets? In accordance with what method of classification?

Carpet classification-classification according to the method of carpet production

Carpets can be divided into mechanical carpets and handmade carpets due to different manufacturing methods. Mechanical carpets include tufted carpets, woven Welton carpets and woven Axminster carpets

- A)

Tufted carpet, the carpet is a large category of mechanical carpet, it is not the warp and weft interweave but the pile yarn through the needle inserted in the carpet base cloth, and then through, after the process of holding the glue from the city. Because the carpet production efficiency is higher, therefore is the hotel decoration preferred carpet, is cheap

- B) woven

Wilton carpet, the carpet is through warp yarn, weft yarn, pile yarn woven three yarn, after the warp gluing, Cashmere and other finishing process. Because the carpet technology originated in the British Wilton area, it is called Wilton Carpet. This loom is double-layer fabric production efficiency is relatively fast

- C) woven

The Axminster carpet is also made up of Warp, weft and pile yarns, which are then glued and sheared. The carpet is made from a single-ply, low-speed, British Axminster, which is only 30% as efficient as the Welton loom, making it one of the highest-end mechanical carpets.

- D) other

Hand-woven carpets

- Hand-stitched gunshot carpet

- by function of carpet use

- A) commercial carpets

Broadly speaking, it refers to all carpets except for domestic and industrial carpets. Commercial carpets are only used in hotels, hotels, office buildings, offices, restaurants and other places in China. In the United States and western developed countries, commercial carpets in addition to the above-mentioned places of use, it has been widely used in airport terminal building, Dock Wave Boat Hall, Station Waiting Hall, Supermarket, hospital, School, nursing home, nursery, cinema and other places, and with the economic development and social progress, the use of surface carpet will gradually increase the scope of coverage will be more extensive.

- B)

Household carpets, just as its name implies, are used at home. In our country, household carpets are still parked on pieces of carpets, because the decoration of Chinese families is still largely based on wooden floors, whereas in the western developed countries, the family uses the carpet is by the full shop and the block carpet unifies, the Chinese family uses the carpet the potential to be very big

- C) industrial carpets

Industrial carpets from home to abroad, is still limited to cars, aircraft, passenger ships, trains and other decorative use.

3, according to the different classification of raw materials

Pure wool carpet-mostly made of wool as the main raw material.

Chemical fiber carpet-(synthetic fiber) using nylon fiber (nylon) , polypropylene fiber (polypropylene fiber) , polyacrylonitrile fiber (acrylic fiber) , polyester fiber (polyester) , set-type silk, silk, PTT and other chemical fibers as the main raw materials.

Plastic carpet-made of polyvinyl chloride resins, plasticizers and other auxiliary materials.

- according to the raw material of the carpet

General with what fiber to do cashmere yarn, what is traditionally called carpet, such as wool yarn as raw materials called wool carpet; to blend yarn as raw materials of the carpet generally contains wool ingredients, so called wool blend carpet; Nylon carpet is made of nylon. Common carpet yarn with fiber raw materials are divided into natural fibers, chemical fibers and blended three. Among them, natural fibers are wool, silk, cotton and jute, chemical fibers are viscose staple fiber, nylon b CF filament and staple fiber, acrylic staple fiber, polypropylene B CF filament and staple fiber and polyester staple fiber; The blends are wool/nylon, wool/viscose, wool/acrylic, wool/polyester and wool/jute.

- Wool carpets

Wool carpets are made of wool as the main raw material. It has fine hair, with natural elasticity, pressure can quickly restore the original; the use of natural fibers, without static electricity, not easy to dust, but also has a natural flame retardant. Pure wool carpet design is exquisite, color is elegant, not easy to aging, fading, with sound-absorbing, warm, comfortable feet and other characteristics.

In addition, woven wool carpet according to the different wool content of cashmere yarn can be divided into:

- Pure wool carpet: wool content ≥95% ;

- Wool Carpet: 80% ≤ wool content < 95%

- Wool blend carpet: 20% ≤ wool content < 80% ;

- blended carpets: wool content < 20% .

- Synthetic carpet

Chemical fiber (synthetic fiber) carpet nylon fiber (nylon) , polypropylene fiber (polypropylene) , polyacrylonitrile fiber (acrylic) , polyester fiber (polyester) , set wire, PTT and other chemical fiber as the main raw materials. Its biggest characteristic is wear-resistant, at the same time to overcome the shortcomings of pure wool carpet easy to corrosion, mildew;.

-- classified by carpet texture

Even if the use of the same production method of carpet, but also due to the use of raw materials, pile form, pile height, feel, organization and density factors, will produce a different appearance of carpet. Common types of carpet top texture are:

1.

Plush carpet is the most common kind of cut carpet, pile length of 5-10mm, the surface of the carpet can emerge a root of broken pile, flat and uniform.

- Velvet carpet

The pile length is about 5mm, the pile on the blanket surface is dense, producing a velvet-like effect.

- Saxony carpet

The pile length is about 15mm, and the pile yarn is processed by twisting and heat setting. The pile produces the effect similar to that of optical fiber, and has a full texture.

- Twist the carpet

That is, bended yarn carpet. The twist of pile yarn is higher, the blanket surface has a hard touch and strong elasticity. The direction of the pile is not certain, so the blanket surface has a special feeling and personality.

- Long pile carpet

Pile length in more than 25mm, both thick and long, thick blanket surface, showing an elegant effect.

- Flat pile carpet

Pile is circular, ring high consistent and tidy, than the cut pile has a moderate stiffness and smoothness, comfortable walking.

High and low pile carpet (including multi-layer high and low pile)

The change of feeding length of pile yarn produces pile ring height, the carpet surface has the level of fluctuation, some form the geometric pattern, the carpet has the three-dimensional feeling.

- Cut/pile carpets (incl. flat cut/pile carpets)

The height of the cut-down part of the general carpet is higher than the height of the loop pile, in the trim, leveling cut pile pile does not hurt the loop pile pile, two kinds of pile mix can form the geometric pattern of the carpet surface, plain color jacquard effect. Flat cut/circle carpet cut technology content is relatively high.

8.Flat carpets

That is, in the carpet on the carpet without vertical pile, as the result of a flat carpet, which is part of the needle carpet roll in the carpet surface pull hair, that is, the texture of hair carpet.

According to the types of carpet products

1.

This kind of carpet is generally in the range of 3.66-4m, full shop that is, spread in the room between the two walls of all the ground, laying place when the width of the room is wider than the carpet width, it can be cut and spliced according to the condition of indoor area in order to meet the requirements of full laying. The bottom of the carpet can be bonded directly to the ground with glue, and it can also tighten the surface of the carpet so that there is little slip between the carpet and the ground, and the method of locating the roots of the surrounding walls with nails. Carpets are commonly used in living rooms, wards, conference rooms, offices, halls, guest rooms, corridors and other occasions.

- A blanket

The shape of the carpet is rectangular to block as a unit of measurement, most of the blocks of carpet is woven carpet, fine workmanship, patterns complex and colorful, high-grade has a certain value of art appreciation. Block blanket width is generally not more than 4m, and the length and width of the appropriate ratio. Block blanket is spread on the ground, but with the ground is not glued, can be arbitrary, at any time spread or rolled up for storage. Block carpet in addition to laying can also be hung on the wall as a tapestry, but also the use of front foot carpet, elevator carpet, art mats and so on.

- Piece the blanket together

Patchwork blanket also calls carpet brick, its outline size is 500mm × 500mm generally, also have 450mm × 450mm or rectangular. The blanket surface is generally tufted class, backing and middle lining cloth is more fastidious. Finished products have a certain stiffness, laying can be bonded to the ground, can also be laid straight ground. The structure of the patchwork blanket is stable and beautiful. The surface of the blanket can be printed or pressed into patterns. In the handling, storage and terrain-based assembly, replacement and assembly of blocks are very convenient. In particular, high-rise buildings, ships, airports, computer rooms and office accommodation are very suitable, in recent years the domestic market is very active.

What are the standards for carpet laying? What are the standards for carpet laying works?

Construction Standard for carpet laying engineering

- The interior decoration must be finished before the carpet is laid. All the heavy-duty equipment in the room have been put into place and have been tested, run, and all of them have been verified to meet the standard of conformity.

- Laying floor carpet of the base, the surface requirements of smooth, smooth, clean, if there is oil, should be used acetone or turpentine wipe clean. If for cement floor, should have a certain strength, moisture content is not more than 8% .

- Carpets, cushions and adhesives should be checked to see if the quantity, varieties, specifications, colors, patterns and so on meet the design requirements, if it is suitable, it should be stored in dry warehouse or room according to its species and specifications. To pre-shop before use, with flowers, number, to shop design according to the number of access.

Should be laid in advance of the room carpet, walkways and other around the skirting board done. The bottom of the skirting board construction technology, should leave the ground about 8mm, in order to cover the carpet burrs under the skirting board.

Four. Before large-scale construction should first put out the construction sample, and do the sample, after the quality inspection department qualified to organize the construction according to the sample requirements.

Carpet laying engineering operation process:

- Technological Process: basic treatment → elastic line, sleeve, grid, positioning → carpet cutting → nail barbed plate tapestry bar → laying cushion → laying carpet → detailed treatment and cleaning

- Mobile laying: refers to the use of adhesive paste in the base of a method, that is, not fixed with the base of the laying around the corner can be repaired. Generally only applicable to decorative process carpet laying.

- Fixed laying operations:

1) grass-roots treatment: laying the carpet of the grass-roots, generally cement floor, but also can be wood floor or other materials of the ground. Require a smooth, smooth, clean surface, if there is oil, should be used acetone or turpentine wipe clean. If for cement ground, should have a certain strength, moisture content is not more than 8% , surface leveling deviation is not more than 4mm.

2) elastic line, set square, division, location: according to the specific requirements of the design drawings for different parts and rooms for elastic line, set square, division, if the drawings have provisions and requirements, then strictly in accordance with the drawings construction. If the drawings do not have specific requirements, should be symmetrically find and elastic line can be positioning laying.

3) carpet cutting: carpet cutting should be in a relatively broad area centralized and unified. Be sure to accurately measure the room size, and according to the room and used carpet model one by one registration number. Then according to the room size, shape with cutting edge machine cut carpet material, each carpet length than the room is about 2cm long, width to cut the size of the carpet after the edge line calculation. Elastic line to cut the edge, and then from the back of the blanket with a hand cutter to cut, after cutting rolled into a volume number, put into the number of rooms, large area of the room should be in the construction site cut stitching.

4) nail barbed plate tapestry: Along the edge of the skirting board around the room or corridor, use high-strength cement nail to nail the barbed plate on the base (nail towards the wall direction) , the distance is about 40cm. The backstab board should be 8 -10 mm away from the baseboard surface for fastening the Backstab Board.

5) lay the liner: use the point-stick method to brush the liner 107 glue or polyvinyl acetate latex, stick to the ground base, to leave the barbed plate about 10mm.

6) carpeting:

- Stitching carpet: lay the cut carpet on the cushion, then roll up the carpet and sew it at the joint. After stitching, use plastic tape on the seams to protect the seams from being torn or raised, then lay the carpet flat and stitch the seams with a bent needle.

- First, a long side of the carpet is fixed on the barbed board, the Burr side is covered under the baseboard, and the carpet is stretched with a carpet support. While stretching, press your hand against the carpet support and knee it, pushing from side to side, step by step. If it is not leveled once, repeat until it is leveled. Then fasten the carpet to another barbed strip to cover the rough edges. The carpet grew out and was cut off with a cutter. After stretching in one direction, stretch in the other direction until all four sides are secured to the barb board.

- When laying sticky carpet, first in the room side brush adhesive, lay the carpet has been cut in advance, and then use carpet support, pull to both sides; then along the wall brush two adhesive, carpet press flat cover edge.

7) detail treatment and cleaning: to pay attention to the treatment of the door and door frame, walkway and hall, the ground and pipe root, radiator, groove box, walkway and toilet door, stair steps and corridor platform, inner door and outer door, different color carpet joints and baseboards and other parts of the carpet set cut and fixed and edge covering work, must be firmly bonded, there should be no exposed, after looking for patch, etc. . Carpet laying finished, fixed after the mouth strip, the application of vacuum cleaner clean, and the carpet surface off the fluff thoroughly clean.

Cost staff guidance: decoration carpet laying several kinds of loss understanding

Decoration carpet laying several kinds of wear and tear understanding

The first thing to talk about is construction losses.

To give a simple example, the construction of a room to lay a carpet. The size of the room structure is 4000 × 8000, the actual area of carpet to be laid should be 3720 × 7720, the market can be suitable for laying the room carpet width of 4000, as the carpet door width can not and can not fully meet the size of the room to be laid, which is bound to produce loss, this loss we call the construction loss. Then the carpet construction loss of the room for example is the ratio of the carpet input area of 4000 × 7720 = 30.88 square meters to the actual carpet coverage area of 3720 × 7720 = 28.72 square meters, that is (30.8828.72-1) × 100% = 7.52% ;

If the size of the room we constructed is 3800.8000, then the construction loss is (30.8827.17.1) × 100% = 13.65% . As the quota system, the compiler has been fully considered and made a comprehensive determination, the carpet laying construction loss is set at 10% , and the provisions of this loss is generally not adjusted.

Therefore, in actual operation, whether we encounter the first case or the second case, the construction losses are calculated by 10% , its quota content is 1.10.

And then there's the shear loss.

We know that carpeting in standard hotel rooms generally requires non-jointing laying, while standard hotel rooms have bathrooms, bathrooms are not carpeted, which requires us to use the original carpeting, another loss, the shear loss, occurs when another piece is cut off from the actual spread area.

Still according to the first example above, the room has an outsourced bathroom with a dimension of 2,000 × 2,400. It has to be cut off from the original 28.72 square meters of actual floor space of 2,000 × 2,400 = 4.80 square meters, then its shear loss is 4.8028.72 × 100% = 16.71% , so the carpet laying loss of this room should be (1.1671.1.1.1) × 100% = 28.38% , and the carpet laying content of this room should be 1.2838.

Some people have proposed that since there is a back shear loss, then the front of the construction loss should also be calculated.

Because we can see from the analysis of the above example, carpet cutting is carried out on the actual area, and when we calculate the actual area from the input area, it has produced the construction of carpet loss, so we can not because of the shear loss of the carpet, the construction of the carpet to ignore the loss.

How to buy carpet? Carpet grade classification, carpet quality choice (2)

Grade classification of carpet

(1) choice of carpet variety:

A, tufted carpet beautiful and durable, is a popular mid-range products.

B, woven carpet gorgeous and comfortable, is the mechanism of high-grade carpet products.

C, needle-punched carpet is suitable for replacement cycle frequent places, is the mechanism of low-grade carpet products.

D, hand-knotted wool carpet, hand-tufted wool adhesive back carpet, hand-knotted silk carpet is a high-grade indoor decoration.

Consumers in the choice of carpets should be based on the specific circumstances of each family to choose different grades of carpets. Such as: indoor if there are wheelchairs, baby carriages and other rubber-tired vehicles often activities, should choose pressure-resistant, easy-to-clean with synthetic fiber woven carpet. If the room with large flow of people lays carpet, should choose tufted pile quality is high, density is bigger, and wear-resistant tufted pile pile carpet. For families with young children, should choose corrosion-resistant, pollution-resistant, easy to clean, deep color synthetic fiber woven carpet.

(2) the choice of carpet size: the choice of carpet size specifications should also be in line with the function of the room. Usually bedroom furnishings are simple, can be purchased over the carpet and the living room can be purchased high-grade use of wool fiber or nylon fiber woven blanket.

Third, the choice of carpet quality

The quality of carpet products is mainly judged by the test data, but also by some simple empirical selection methods:

(1) carpet pile density: you can touch the carpet by hand, the pile quality of its products is high, the density of the carpet surface is full, such a good carpet elasticity, stampede resistance, wear resistance, comfortable and durable.

Consumers are reminded not to adopt the method of choosing long plush to choose carpets. On the surface, the plush looks good, but the pile density is sparse, and the pile is prone to fall and deformation. Such carpets are not resistant to trampling, easy to lose the unique performance of carpet, not durable.

(2) color fastness: colorful carpet, soft texture, beautiful and generous. When choosing carpet, you can rub the carpet surface several times with your hands or test cloth to see if there is any color on it. If there is any color, it means that the color fastness of the product is not good, causes the carpet to appear in the laying use discoloration and the fading, but affects the carpet in the laying use in the beautiful effect.

(3) carpet backing peeling strength: the back of tufted carpet is bonded with a layer of mesh undercloth by latex, and the peeling strength index ≥25N is defined according to the standard. Consumers in the selection of this kind of carpet, you can use your hand to gently tear the base cloth, look at the degree of adhesion, such as adhesion is not high, the base cloth and blanket body is easy to separate, so the carpet is not durable.

(4) look at the appearance of quality: consumers in the choice of carpet, to check the carpet surface is flat, carpet edge is flat, there is no defect, grease spots, color difference, especially when buying tufted carpet to check whether the back of the carpet off-lining, glue penetration, etc. , to avoid the carpet in the laying use of the drum, inequality, and lose comfort, aesthetic effect.